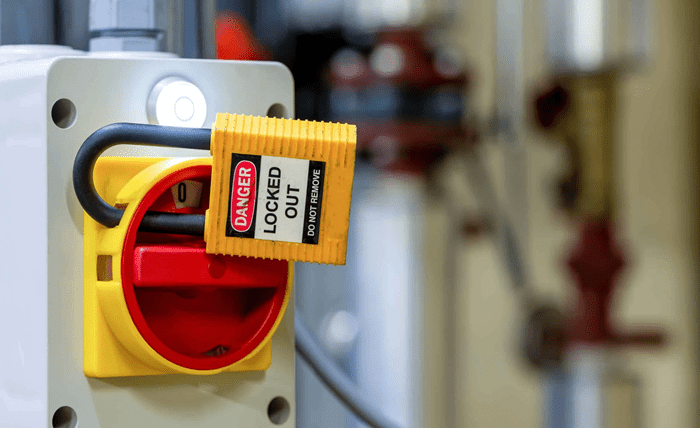

Lockout tagout, or LOTO, is a general safety procedure applied to ensure that dangerous machines are turned off properly and not started up again before the completion of maintenance or repair work. It is the procedure of shutting down dangerous power sources that prescribes “locking” and “tagging” out equipment so that no one turns it on, spelling out the danger.

LOTO practices secure employees against the unexpected start-up of machinery or the release of hazardous energy during service activities. It teaches workers how to switch off equipment properly and apply locks and tags, so that people around them won’t start the equipment before the locks are removed. Many accidents and injuries are avoided with the implementation of these procedures.

Understanding Lockout Tagout Essentials

The lockout tagout training should begin with knowledge on the type of energies that are present at workplaces. They may be electrical, mechanical, thermal, chemical, or any other class. It encompasses all forms and types of energy sources that might require control. The training is to make workers identify what kind of energy they would have to deal with and what hazards such a type of energy may pose.

The training also advises on how to use the appropriate lockout-tagout equipment. This equipment includes locks, tags, chains, wedges, etc. Each of these equipment is designed in such a way that they suit different types of machinery and machines. They serve the crucial function of holding equipment in a safely shut state.

Key Aspects of Effective Lockout Tagout Training

Key components of effective lockout tagout training include teaching workers how to identify the appropriate lockout devices and how to apply them correctly. Workers will learn specific steps of how to safely shut down equipment when necessary, and avoid any inadvertent start-up.

Training should also incorporate the process of tagging out, where a tag on the lock is made to show who locked out the machine and the reason for the lockout. This tag should be made with a warning not to operate the machine until the tag is officially removed. This way, important information can be passed on to each and every employee, and everyone is free from confusion or errors while at work.

So, basically, after the maintenance work is complete and the machine is already safe to be re-energized, the worker who put the lock and tag at the installation should also be the one to remove them. This ensures that the person who knows the most about the situation is the one who feels that it is safe to resume operations, and does so.

Conclusion

Lockout tagout training is essential for workers as it helps in safeguarding them from potential hazards. The better the workers know key points and methods that relate to LOTO, the more they can maintain an appropriate working environment and avoid accidents. After all, the ultimate goal of LOTO is to ensure the safety of everyone through the effective control of hazardous energies.