Introduction:

In the dynamic landscape of electronics manufacturing, the transition from through-hole technology to surface mount technology (SMT) has been a pivotal advancement. Surface mount devices (SMD) play a crucial role in this evolution, revolutionizing the way electronic components are mounted on circuit boards. This article explores the fundamentals of surface mount devices and delves into the significance of SMT line in modern electronics manufacturing.

Surface Mount Devices (SMD):

Surface mount devices, commonly known as SMD, are electronic components that are designed to be mounted directly onto the surface of printed circuit boards (PCB). Unlike through-hole components, which are inserted into holes drilled in the PCB, SMDs are soldered directly onto the board’s surface.

- Types of Surface Mount Devices:

Resistors and Capacitors: SMD resistors and capacitors are compact, space-saving components crucial for miniaturizing electronic devices.

Integrated Circuits (IC): SMD IC are prevalent in modern electronics, offering high-density packaging and improved performance.

Transistors and Diodes: SMD transistors and diodes contribute to the efficiency and miniaturization of electronic circuits.

- Advantages of SMD:

Space Efficiency: SMD enable the design of smaller and lighter electronic devices, promoting miniaturization.

High-Speed Assembly: SMT assembly processes are faster and more automated than traditional through-hole methods.

Enhanced Electrical Performance: SMD exhibit better high-frequency characteristics due to reduced parasitic capacitance and inductance.

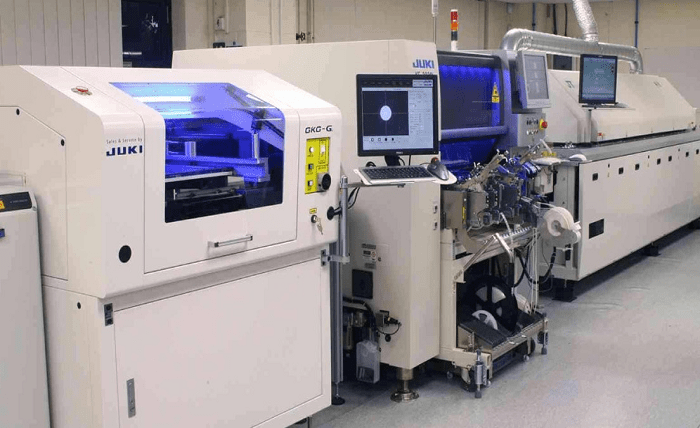

SMT Line And Their Role:

Surface mount technology (SMT) lines are assembly lines specifically designed for the efficient and automated placement of surface mount devices onto PCB. These lines consist of several key components and stages that ensure a seamless and precise manufacturing process.

- Stencil Printing:

- Before components are placed, solder paste is applied to the PCB through a stencil. This step ensures accurate placement of solder on the pads where the components will be attached.

- Component Placement:

- Automated pick-and-place machines precisely position SMD onto the solder paste-covered pads on the PCB. These machines can handle a variety of component sizes and shapes with high accuracy.

- Reflow Soldering:

- The assembled PCB then pass through a reflow soldering oven, where the solder paste melts, creating strong and reliable solder joints. This process ensures the secure attachment of SMD to the PCB.

- Inspection and Quality Control:

- Automated inspection systems check the solder joints and the placement of components to identify any defects. This step ensures the production of high-quality PCB.

- Testing:

- The final PCB undergo functional testing to ensure that all components are functioning correctly. This step is crucial for identifying and rectifying any issues before the final product is assembled.

Conclusion:

In conclusion, surface mount devices (SMD) have revolutionized electronics manufacturing, enabling the creation of smaller, more efficient, and high-performance electronic devices. The use of SMT line in the manufacturing process ensures precision, speed, and reliability in assembling these components onto printed circuit boards. As technology continues to advance, the significance of SMD and SMT line will only grow, contributing to the ongoing evolution of the electronics industry.