An injection molding tool is a specialized tool used in the injection molding process to create plastic parts and components. It is sometimes referred to as an injection plastic mold or an injection die. This is comparable to the high pressure die casting method that is used to make metal alloy parts; both molding processes are widely employed worldwide in all industries. Of course most of companies are buying injection molding tool from China mold companies today.

The method of injection molding involves pumping molten plastic material into a cavity in an injection mold, allowing it to cool and solidify to take on the shape of the mold as intended. An essential part of the molding process is the injection molding tool, which is made by skilled manufacturers due to its complexity.

Key components of an injection molding tool include:

The process of making an injection molding tool is quite complicated, so if you need one for your project, we advise you to find a manufacturer to assist you. A professional manufacturer is needed to complete the job. Some of the main parts of an injection molding tool are as follows:

Mold Foundation : The core structure of an injection molding tool, the mold base, provides support for the cavity, core, and ancillary components. It often features integration points for connecting the mold to the injection molding machine. Without the foundation of the mold base, the injection molding process cannot commence.

Cavity and Core: The cavity and the core are the two basic components that make up a mold. The molded product’s ultimate shape is created by the fitting of these components. Naturally, the cavity and core contain a large number of tiny parts, such as screws, sliders, lifters, sleeve pins, and surface insert pins.

Runner System: The liquefied plastic, heated to a fluid state, is forced through the channels and gates within the runner network, filling the mold cavity. This intricate system ensures the material’s homogenous distribution throughout the injection molding apparatus.

Cooling System: To regulate the injection molding tool’s temperature throughout the molding process, a cooling system is included right into the tool. Achieving constant cycle times and part quality requires proper cooling.

Ejector System: The completed object is pushed or ejected out of the injection molding tool using the ejector system once the plastic has cooled and set in the mold cavity. An essential stage in the entire injection molding process is this portion removal.

Injection molding instruments are usually made to order and can be rather intricate. The type of plastic being used, the volume of manufacturing, and the required qualities of the finished product all have a role in the materials choice for the mold. Injection tools are commonly made of steel and aluminum.

Types of Injection Molding Tools

Injection molding tools come in a variety of forms, and each one is appropriate for a certain set of needs and parts. A number of criteria, including the part’s complexity, volume required, size, material qualities, and economic concerns, influence the choice of injection molding tool type. Some typical kinds of injection molding tools are listed below:

- Injection molding tools with a single cavity or many cavities:

- Single Cavity Tools: These injection molding tools generate a single item per cycle within each mold impression. They are suitable for both high and low volume production runs.

- Multi-Cavity Tools: These tools may produce many pieces in a single molding cycle since they have various cavities. They are employed in high-volume manufacturing to lower unit costs and boost efficiency.

- Family Tools: A family tool is a kind of multi-cavity mold that can make several parts at once. This could reduce the cost of the tool because it is highly helpful for certain small parts and low volume molding parts.

- Hot Runner Tools: These tools pour molten plastic straight into each cavity via a network of heated pipes known as “hot runners.” This reduces cycle time and material waste by doing away with the necessity for a sprue and runner system. This is typically employed in large-scale, high-volume manufacture of parts; certain molds may include many hot drops.

- Cold Runner Tools: These are runner systems in which molten plastic is forced via cold channels. Typically, the spure is thrown to the cavity and core, where it solidifies with the molding component. For the needs of low volume production, cold runner tools are utilized.

- Insert Tools: Sometimes referred to as overmolding, insert tools involve molding a metal insert or another solid material together with molded elements. Adding features like threaded inserts or strengthening pieces can be done with this.

- Overmolding/Two-Shot Tools: Similar to insert molding, overmolding combines two distinct materials, but in this case both are plastic, forming a single unified component. Often, the second layer, known as the overmold, utilizes a flexible polymer like thermoplastic elastomer (TPE) for enhanced grip or comfort. While two-shot molds enable the injection of two different materials or colors within a single cycle, this method necessitates a significantly expensive 2k injection molding machine.

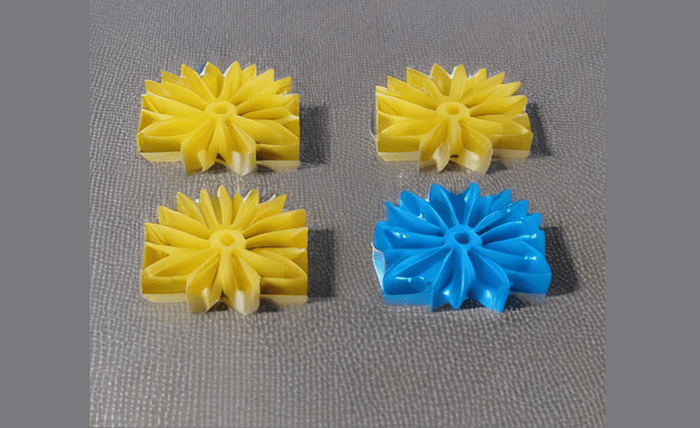

- Prototype Tools: Prior to full-scale production, prototype parts are tested and validated through low-volume production using prototype tools. Prototypes made by CNC machining and 3D printing can occasionally be used in place of these instruments.

The type of injection molding tool that is used for a project will depend on its particular requirements. If you are unsure which tool is best for your project, call us and we will assist you choose the best tooling solution.

Design Considerations for Injection Molding Tools

A number of considerations must be made while designing injection molding tools in order to guarantee the manufacturing of high-quality plastic components. Design is one of the most important factors in producing high-quality, long-lasting injection molding tools because good design leads to good injection molding tools. The following are some essential design factors for injection molding tools:

- Part Design: Properly designed parts will make injection molding tools easier to use. Balance wall thickness, excellent rid design, draft angle, undercuts, and other considerations should all be included in part design.

- Material Selection: The kind of plastic being used, the volume of production, and the anticipated tool life all influence the choice of mold material. Tool steels like 1.2344, 1.2343, S136, and H13, pre-hardened steels like P20, 738H, and NAK80, and aluminums like 7075 are often used materials for tools.

- Cooling System: One more crucial element to consider when designing injection molding tools is the cooling channels. Proper cooling results in excellent part quality, surface-less deformation problems, shot cycle time, etc.

- Design of the Gate Location: • The injection molding tools are fed through a gate. Achieving the best possible component quality, lowering stress, and minimizing air traps or sink marks all depend on proper gate design.

- Runner System: • A well-designed runner system, comprising the channels that plastic flows through in the mold, will make it easier to fill the part and less likely that it would deform or have sink problems.

- Ejection System: This mechanism is in charge of removing the molded component from the mold core. A well-designed ejection system will prevent stress marks, warpage, and part damage, among other issues.

- Venting: • Appropriate venting guarantees that gases and air will exit the mold cavity during injection. It always need good venting to make good part

- Draft Angles: Part ejection from the mold is made easier by the use of draft angles. They aid in preventing mold surface scratches. especially for a certain texture surface need. It is recommended to add draft angles that are appropriate for the material and part geometry.

The aforementioned are some general considerations that should be made when designing injection molding tools; there will be additional considerations. If you require injection molding tools, hiring a qualified manufacturer is the only way to ensure the success of your project.

Cost Considerations in Injection Molding Tooling

The economics of injection molding tooling are paramount, This includes high-pressure die-cast molds (aluminum), zinc or magnesium die-cast molds, continuous stamping molds, and gravity die-cast molds, since they considerably affect the financial aspects of manufacturing.. These factors profoundly shape the complete manufacturing process. Here are crucial elements to factor in when calculating injection molding tooling expenses:

- Material Selection: The cost of the injection molding tool is greatly influenced by the material selection. Although higher-quality tool steels cost more than less resilient materials like aluminum, they may provide longer tool life and lower maintenance costs in the long run. Examples of high-priced tool steels are 1.2343, H13, and 8407 (die casting mold), whereas low-cost steels include P20 and 738H.

- Tooling Complexity: Injection molding tools cost higher when parts are designed more intricately. However, if certain action features can be eliminated, the cost of the injection molding tools can be decreased by improving the component design.

- Number of Cavities: Multi-cavity tools can be more expensive than single-cavity molds, but they can help you cut down on cast if your project has more than two components.

- Tool Size: Smaller tools will cost less than larger ones since larger tools need more material and processing.

- Surface Finish: • The cost of injection molding tools will increase with some texture surfaces, and Basic polishing offers less refinement than high-performance polishing tools..

- Tool Steel Grade: The price of various tool steel grades varies. Pre-hardened steel, such as P20 and 1.2738H, is less expensive than hardened steel, such as 1.2344 and H13, since the latter requires heat treatment and additional CNC machining.

- Tolerances and Precision: • High precision injection molding tools will be needed for plastic molding products with tighter tolerances and greater precision. The cost of the injection molding tool will go up as a result.

- Cost of testing: • Mold trials will also incur costs, since many molds require multiple trials before being released into production. This will drive up costs.

The prices of some common injection molding tools are shown above. Additional expenses include surface modification, cost adjustments for injection molding tools, and other related costs.

Applications of injection molding tool

Plastic parts and components are produced by a variety of industries using injection molding techniques. We can state that you require injection molding tools for everything. The following are a few typical uses for injection molding tools:

- vehicle Industry: Injection molding tools are needed for a variety of vehicle products. including door handles, seat covers, dashboards, door panels, external body panels, bumpers, and a variety of additional pieces.

- Consumer Goods: Injection molding is used in the production of a wide range of consumer goods, including toys, kitchenware, storage containers, and the casings for electrical devices. In addition, the wholesale flat irons manufacturers will require injection molding to create the housing or casings for their high-speed hair dryers, air hair straightener, and other tools.

- Medical Devices: • Some medical equipment, such as machines, uses injection molding tools. comprising vials, syringes, IV parts, housings for diagnostic equipment, and other disposable medical parts.

- Electronics and Electrical Components: Injection molding tools are used by the electronics industry to produce electric housings, connections, and casings for devices like computers, routers, smartphones, and power adapters.

- Packaging Industry: • Plastic bottles, caps, containers, and packaging components for food, beverages, cosmetics, makeup, and personal care items are all produced using injection molding.

6. Appliances: A variety of injection molding equipment are used in home appliances, including vacuum cleaner housings, refrigerator parts, and washing machine parts. - Aerospace Industry: Lightweight and strong components, such as external and interior aircraft parts, are produced in this industry using injection molding tools.

- Construction: • To create components including pipe fittings, cable management systems, electrical junction boxes, and insulating materials, the construction sector uses injection molding.

9. Toys and Games: • A large range of plastic molding toys, building blocks, and gaming components are produced by the toy industry by injection molding.

We can state that everything you need for injection molding tools is included in the list above; nevertheless, there are many more industries, like education, sports, travel, and so on.GC Precision Mould Co.,ltd is your go-to source for plastic molds and aluminum die casting China company. We use premium materials like magnesium, zinc, and aluminum to create a wide variety of die-cast parts as well as excellent injection molding and die casting tools.

We tailor our solutions to meet their unique needs, providing bespoke blueprints that adhere to their exact requirements. We offer injection molding tools and die castings for diverse sectors, encompassing automotive, consumer electronics, medical, and industrial machinery.Whether you need one plastic mold or an aluminum die casting service, we have the knowledge and resources to provide exceptional outcomes. Request a quote from us right now.